Printed Circuit Board Assembly

Printed circuit board assembly (PCBA) is the process of soldering or assembly of electronic components to a printed circuit board or PCB. At Hughes Electronics, we are skilled at custom PCB assembly. Being a manufacturer, our services include designing, testing, prototyping and manufacturing followed by complete support. Hughes Electronics is a full-service contract electronic manufacturer specializing in assembly of Surface Mount Technology (SMT) and Through Hole mixed technology Printed Circuit Board Assemblies (PCBA). Our skilled personnel use state-of-the art equipment and years of industry experience to design a control plan to achieve each manufacturing requirement. Program management with attention to detail will ensure customer satisfaction and a job well done. Our industry experience allows us to provide an intelligent response to all your printed circuit board assembly needs.

Our PCB Assembly Capabilities

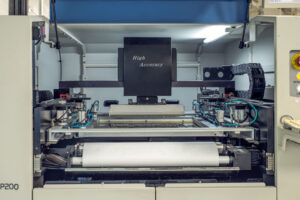

The bulk of the PCB’s we assemble utilize Surface Mount Technology (SMT) and typically include through-hole components. The equipment, components, and mounting process vary with these two assembly methods. You can rest assured that we have tenured experience in place for both technologies.

There are a lot of factors involved when it comes to PCBA. This has to do with the electrical components that are involved in the process. Many PCBs that require assembly use SMT primarily or exclusively, since surface mount assembly is fast and easy to automate. In general, Printed circuit board assembly undergoes numerous production stages, such as:

- Loading

- Screen Printing

- Solder Paste Inspection (SPI)

- Part placement (SMT or Through hole)

- Automated Optical Inspection (AOI)

- Reflow

- Unloading

Hughes Electronics is well-equipped for surface mount, through-hole, and mixed-technology applications using our state-of-the-art machinery. Our innovative capabilities also follow the highest industry standards available.

We work with a wide array of PCB assembly materials, including:

- Fiberglass

- FR-4 glass-reinforced epoxy laminate

- Mylar® film

- Phenolic laminates

- Polyimide (PI)

PCB Assembly Quoting Process

Our objective is to provide a cost effective and accurate quote. Components defined on the Bill of Material account for the majority of the overall cost of a Printed Circuit Board Assembly. We use our preferred vendors to source the global network to find the best price and delivery lead-time available. If we run into problems with obsolescence or lead time, we will identify and discuss the issue so we can find an acceptable alternative. Our policy is to resolve all issues at quote. This time spent at quote allows us to accept an order and proceed without delay.

Design for Manufacturer

Properly designed products will create efficient manufacturing with effective results and lasting reliability. “Design for Manufacture” is imperative to achieving target pricing in a globally competitive marketplace. Our team provides specialized, professional people that analyze the Printed Circuit Board design and the components called out on the Bill of Materials. Our experience and insight will help you shorten your development time to a production ready product.

Types of PCBs that we Assemble

Our facility is equipped and stocked with a wide variety of resources at our disposal, Also, the advanced technology that we employ gives us the ability to assemble three types of printed circuit boards:

- Rigid PCBs: The rigid printed circuit boards are some of the most common PCBs used in assemblies. The thickness and rigidity that the board requires is provided by the solid core of this type of PCB. There are many unique materials that are utilized for producing these PCB bases. One of the most used materials is fiberglass. However, there are other alternative options of materials, such as phenolics or epoxies, though they are less durable.

- Flexible PCBs: Another type of PCB that Hughes Electronics has the ability to produce are the flexible printed circuit boards. These PCBs give a superior flexibility compared to their rigid counterparts. High temperature plastics, such as Kapton is most commonly used material for these PCBs owing to its good blending property.

- Metal Core PCBs: The other type of PCB that we can manufacture is the metal core printed circuit boards. These circuit boards are a quality alternative for typical FR4 boards. As suggested by their name, these boards comprise of a metal core, which allows them to spread the heat efficiently. Thus, heat is dissipated effectively from the board, which helps protect the heat-sensitive components mounted on the PCB.

PCBA Build Process Flow

We know that reliable performance is the result of successfully coordinating a variety of processes and giving proper attention to every step. The core of these steps is our Assembly Process Build Sheet that travels with the product and the Build Folder through all manufacturing steps. Our traveler defines each task and the acceptance criteria. All steps require employee signoff before moving to the next operation. This document is the basis of our Quality Management System to ensure reliable and repeatable performance with lean manufacturing principles.

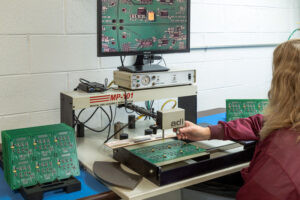

Quality Assurance

Hughes Electronics Products is committed to providing the highest level of Customer Satisfaction and Quality. Providing a quality product on-time and for a competitive price is the foundation of customer satisfaction. We are engaged with our customers to understand the requirements and deliver the results. Our staff is focused on quality improvement and elimination of waste. Self-audits are used to evaluate and improve our processes and our technical capabilities. Analyzing these results also provides insight used to effectively invest in the equipment needed to expand our capabilities and improves our consistency. We are also ISO 9001:2015 certified as well.ISO certification is an industry standard quality program to ensure repeatable quality products.

On-time Delivery

Hughes Electronics knows the importance of shipping your order on time. This is a metric we measure and evaluate during all management review meetings. Failures and trends are identified and discussed with the appropriate supervisor. Effective solutions are implemented as needed to achieve the ultimate goal of 100% on-time PCBA shipments.

ESD Safe

Hughes Electronics is an ESD safe manufacturing site. Our ESD program is designed to comply with industry standard ANSI/ESD S20.20-2014. All employees test their foot straps and wrist connections before they enter the manufacturing floor. We use a dissipative floor solution that absorbs human charge to create a zero potential for Technicians working on their feet. ESD shop coats are worn by all. Each coat has a plug-in terminal that electrically connects the wrist to the terminal then to ground for all employees seated at their workstations. Ground detection monitors are installed at all benches to ensure each Technician has a reliable connection. The monitor will sound an alarm if the connection to ground is lost.

To get started on your Printed Circuit Board Assembly project, contact us today.