Surface Mounted Device Assembly

Modern Printed Circuit Board Assemblies mainly consist of Surface Mount Devices (SMD). Surface Mount Devices are electronic components placed and soldered onto the surface of a printed circuit board. The transition to Surface Mount Technology is driven by the advantage of placing smaller components that perform the same but occupy less space on the Printed Circuit Board. This advantage allows for greater computing power in smaller sized Printed Circuit Board assemblies. The cell phone evolution is the biggest example of SMD based Printed Circuit Board Assemblies providing breathtaking performance in a handheld device. We support a wide range of markets providing Prototype to Production PCBA’s featuring Surface Mount Technology.

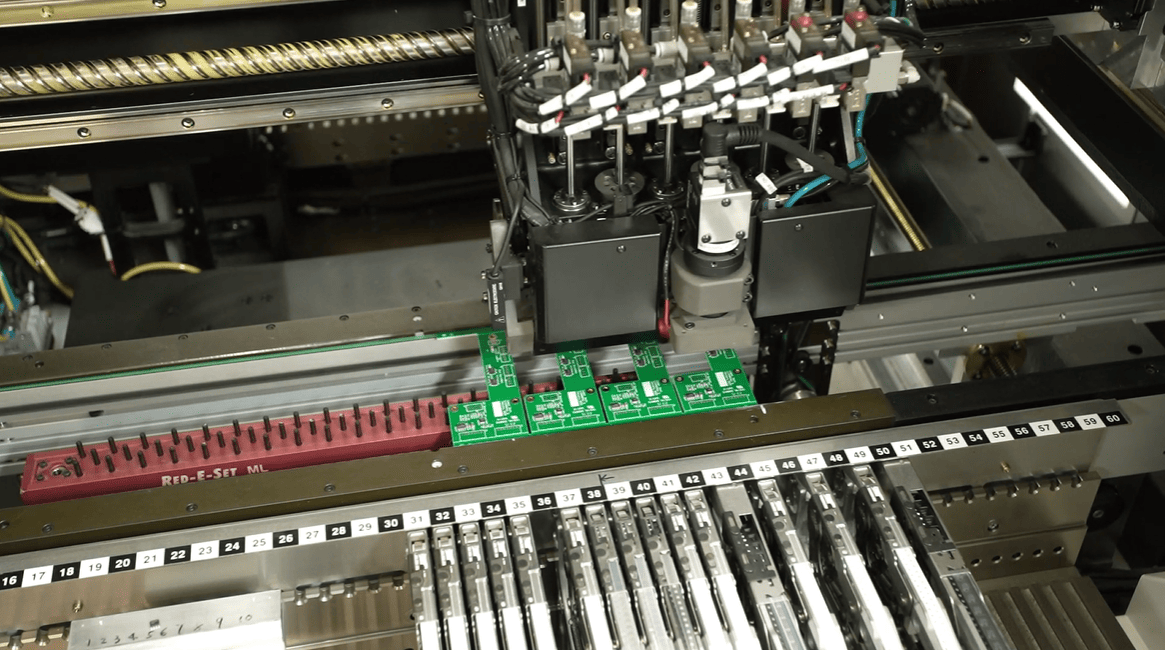

Pick and Place

Our production lines feature automated SMT placement services with true “on the fly” vertical alignment technology capable of all fine pitch Integrated Circuits, micro–Ball Grid Array’s, and 01005 package chip parts. Electrically driven feeders yield precision placements with production intent speed. Our Technicians follow an in-house programming process that includes double checking the SMT Program to the Feeders and the customer Bill of Materials. This process includes a QA person with a second set of eyes to ensure accurate programming with efficient changeover from one build to the next.

Precise Reflow Soldering

Effective Reflow soldering of SMT placements is determined by matching the oven temperature profile on the Printed Circuit Board Assembly to the manufacture recommended Reflow Solder Profile of the solder paste being used. Requirements are unique to each PCB assembly. This temperature profile is dependent on parameters that include bare PC board layer count, bare PC board finished coper weight, and the size and type of components placed onto the PC board assembly. Because of this, all new surface mounted device assemblies are profiled with an industry standard KIC 2000 Reflow Solder Profiler. This process step will provide Reflow Oven settings that ensure an optimized result given the unique characteristics of each Printed Circuit Board Assembly.

AOI Inspection for Surface Mounted Device Assembly

SMT assembly is a dynamic process dependent on many variables. Automated Optical Inspection is run on all our SMT Assemblies to inspect the physical results of the build process. AOI with 3D technology uses high resolution cameras to make precise measurements and characterizations of each SMD placement. Measurements are taken in microns to confirm IC’s placed are soldered flat to the board with no lifted leads. Inspections are done to locate and confirm the presence of a component, the polarity mark of a component, the part number of a component, shorted leads and component skew. Advanced color imaging is used in conjunction with complex software Algorithms to image all solder fillets and inspect them to preset acceptance criteria. AOI inspection provides additional confidence to move the surface mounted device assembly forward to the through hole assembly process.

X-Ray Inspection

BGA and Leadless package components require X-Ray inspection to evaluate solder joints not seen with Automated Optical Inspection. Our system uses a 10-micron MicroTech X-Ray source that provides crystal clear magnification from 7 to 2000X. Auto BGA analysis with void measurement is the feature process. A five-axis positioner allows an operator to produce accurate images from any angle of analysis.

To get started on your Printed Circuit Board Assembly project, contact us today.