Wave Soldering is the production method favored for through-hole only assemblies which involves inserting leads of components into drilled holes in the Printed Circuit Board and soldering on the opposite side. The evolution of Surface Mount components has replaced the majority of through hole assembly components originally designed onto Printed Circuit Board Assemblies. Even with the technology shift, many designers still favor or require THT components for design specific placements. These placements include connectors, capacitors, relays, transformers, potentiometers, LED’s, etc. Our technicians are highly skilled soldering operators. Our solutions include selective wave soldering machines with Nitrogen enhancement, traditional wave soldering or manual soldering. Some assemblies will require more than one of these processes listed above.

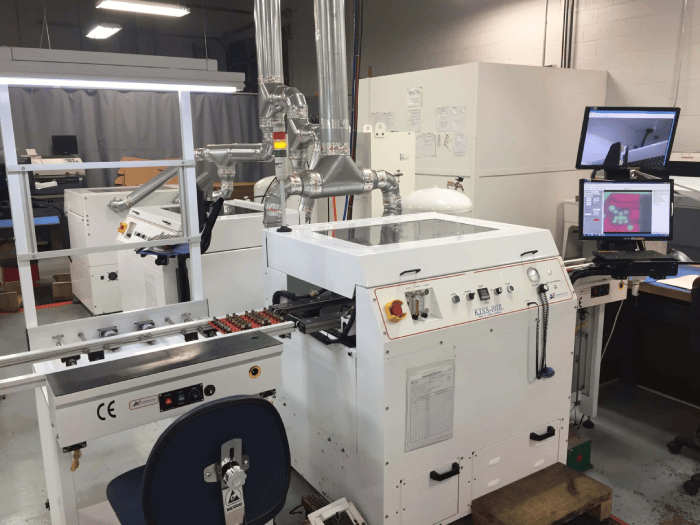

Selective Solder for Through Hole Assembly

Selective Soldering provides a repeatable Robotic Motion with production quality results for through-hole technology components. These machines are used as an alternative to manual or wave soldering. Most assemblies now have Surface Mount Devices soldered on both sides of the Printed Circuit Board Assembly. With Selective Soldering each through-hole lead can be soldered without disturbing SMT components on the boards adjacent to these through-hole solder joints. This is a program based process that locks the PCBA in place while it sprays flux at the solder point then brings a fountain of molten solder to this programmed location. The result is a precision controlled production intent solder joint without the time and expense of fixtures required to mask SMT components during Wave Soldering. Removable solder pots allow us to solder “Lead-Free” assemblies then change over to “leaded” assemblies in the same shift.

Nitrogen Enhanced Selective Soldering

Hughes Electronics Products uses Nitrogen Generators to create pure nitrogen from the compressed air system used throughout the shop. Soldering in a Nitrogen Atmosphere is an essential part of our selective soldering process. Soldering without a nitrogen atmosphere leaves solder joints open to the possibility of oxidizing and the loss of long term reliability.

Wave Solder

Wave Soldering is a production method favorable for through hole assembly or mixed technology assemblies with all components mounted on one side of the printed circuit board. We do have customers with Thru-Hole only legacy products that utilize our wave solder line. Wave Solder is a standard process offered by all full-service Contract Electronic Manufactures.

To get started on your Printed Circuit Board Assembly project, contact us today.